Inside the Nanoworld: DVC Students Explore Multibeam’s Cutting-Edge Technology

The Silicon Valley Leadership Group Foundation had the opportunity to bring 25 engineering and computer science students from Diablo Valley College to Multibeam Corporation, one of Silicon Valley’s most innovative semiconductor equipment companies.

The visit was part of the Bay Area K-16 Collaborative’s worksite visit series, which creates structured opportunities for students to explore high-demand industries and understand how their academic training connects to real careers. Interest in the Multibeam visit was remarkable. Within days of DVC announcing it, more than 50 additional students joined the waitlist, a clear sign of how strongly students want exposure to the semiconductor sector.

Semiconductors power nearly every aspect of modern life. Phones, cars, computers, and medical devices all depend on chips built with extraordinary precision, and manufacturing those chips requires tools capable of creating features at the nanometer scale. Multibeam is among the companies advancing this frontier. Its multicolumn electron-beam lithography (MEBL) platform uses many miniature e-beam columns operating in parallel, enabling maskless, direct-write patterning of silicon wafers for advanced packaging, photonics, and high-mix production.

For the Bay Area K-16 Collaborative, exposing students to companies working at this level of technology helps ground academic preparation in the realities of a rapidly transforming industry.

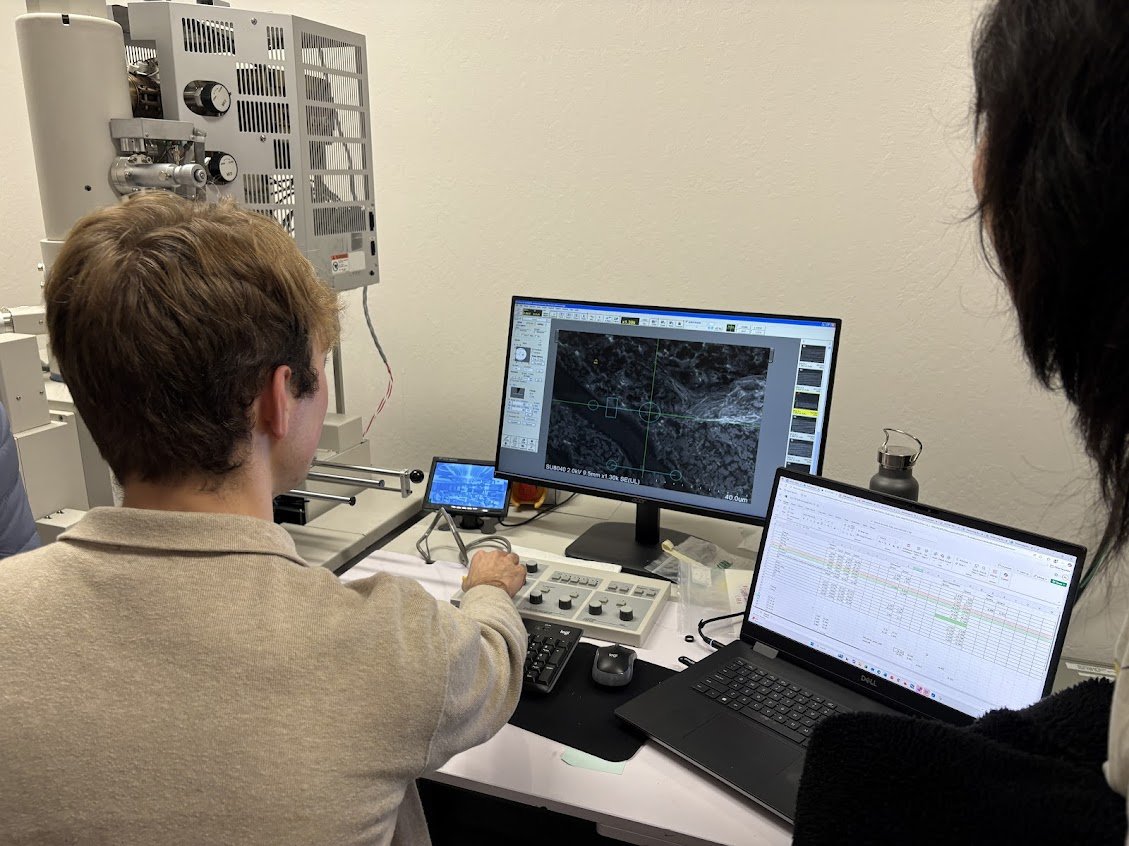

To help students understand the complexity of these systems, Multibeam created a hands-on experience made up of five small-group technical stations. At one station, students viewed an electron beam microscope and learned how electron imaging reveals structures too small for optical lenses. Another station explained how miniature electron beam columns form the core of Multibeam’s patterning system. A third demonstrated the wafer staging platform, where a controls engineer showed how the system positions silicon with extreme accuracy. Additional stations explored materials, physics, and the software pipelines that turn design files into written patterns.

The multidisciplinary nature of the visit resonated strongly with students across electrical, mechanical, and computer engineering. In the Collaborative’s post-event survey, many commented on how the experience helped them visualize the intersection of their coursework. Several noted how valuable it was to see control systems, embedded software, mechanical design, vacuum engineering, and materials science all working together inside a single tool. Nixon Lazo reflected that the visit revealed “the actual depth of how complex these systems are,” while Preston Chin said the conversations and demonstrations “reminded me why I enjoy engineering.” And Huiluan Yie shared that speaking directly with Multibeam staff “helped bridge the gap between theory and execution.”

Inside each station, students were able to match what they have learned in class to real industrial practice. Mechanical engineering students asked questions about vibration control and stage precision. Electrical engineering students were curious about beam stability and sensor feedback. Computer engineering and computer science students explored how massive datasets are streamed to the tool in real time. The visit showed how many directions a student can take within the semiconductor equipment world and how a wide range of engineering disciplines can contribute to the technology.

For the Silicon Valley Leadership Group Foundation, which supports the Bay Area K-16 Collaborative, this visit illustrated the value of coordinated, equity-centered work-based learning. Community colleges like DVC serve a diverse and growing population of future engineers, and giving students early access to cutting-edge environments helps them understand which skills matter, where to focus their studies, and how their educational choices connect to real careers. Many students left with a clearer sense of the pathways available in Silicon Valley and how programs like MESA, engineering clubs, or Tesla START fit into a broader regional workforce strategy.

Multibeam staff expressed enthusiasm about the visit and look forward to supporting future cohorts.

“Hosting these college students in our offices and giving them a firsthand look at the innovations shaping the semiconductor industry was incredibly rewarding. We are committed to helping educate and inspire younger generations of talent that will continue to build and strengthen the U.S. semiconductor industry.”

-Ted Prescop, VP of Technology, Multibeam Corporation

The day also strengthened the relationship between DVC faculty, students, and industry professionals. Several engineers stayed long after the formal rotations ended to continue answering questions, offering advice about internships, and encouraging students to stay the course in their STEM programs. Many students used the lunch and networking time to ask about transfer pathways, day-to-day engineering work, and the traits companies look for when hiring early-career talent. These conversations added a layer of support that students rarely encounter in traditional classroom settings and helped build momentum for continued engagement between DVC and regional employers.